Water Flow Kinetic Energy

Invention For Humanity:

This is a patented device which is intended for furnishing the same goal. It will provide cheaper clean electricity. In addition to this, we hope a certain very small percentage out of the electricity bill will go to a fund to help the poor places to build their electricity facilities. It will be a win-win-win situation that the rich, the poor and the industry all share the benefit of it.

Principle:

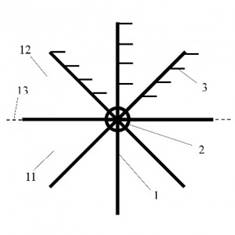

It is simply the principle of the lever that makes these three types of energy device work. The device is basically a turning wheel. But, the crucial difference is that the wheel flaps are free to move so that one half of the device will let go the flow while the other half will stay at their normal position when it submerges in the water current. When it places in the water current, there will always be one half pressed by the oncoming water current to capture flow energy and keep on turning.

Three types of patented energy device bear the same principle. The differences among them are the way of setting the wheel flaps free. LZ-1 and LZ-2 need an internal power supply to power up to open and shut the wheel flaps. It is because it is difficult for a rotating object in water to get electricity from an external power supply. The control of wheel flap movement facilitates LZ-1 and LZ-2 to capture energy in an environment where the current direction is alternating.

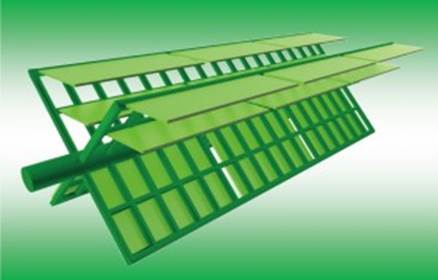

The wheel flaps of LZ-3 can be free to open and shut naturally. Yet, LZ-3 can only be used in a current of steady direction. LZ-3 can be used to capture wind power too. Its wind impact area is 6 times more than the conventional fan-type wind-power generator. Moreover, it can withstand high wind speed.

Flow kinetic power output calculation:

P=(1/2)ρrLv3

Where:

P for power ρ for density of medium which is temperature dependent but the variation is not significant. Water density is about 1000Kg/m3. Atmospheric density is about 1.29Kg/m3.

r for device radius

L for axial length

v for flow speed

In water:-

Provided r=1m, L=1km

In a moderate speed when v=1m/sec P=0.5MW

In a rapid speed when v=3m/sec P=13.5MW

(Minor fictional loss is ignored)

In the Wind:-

Provided r=1m, L=10m

In a moderate speed when v=5m/sec P=0.8KW

In an average speed when v=10m/sec P=6.5KW

In the conventional upper limit when v=20m/sec P=51KW

Above the upper limit when v=30m/sec P=174KW

(Minor fictional loss is ignored)

Advantages over the conventional combustion power generation:

The leveled cost of energy is reduced significantly. There is no direct cost for the renewable energy source. The social cost is reduced significantly.

Advantages over the conventional hydraulic power generation:

It is not necessary to build a dam. The cost of civil work and site development is reduced significantly. It requires much less land resources. It is not necessary to migrate people. It is not necessary to use very high power generators. It can be built in the nearby neighborhood without NIMBY problem. It will use less transmission power line. The environmental damage and ecological damage will be minor. There will be no methane problem. There will be no silting problem. There will be no risk of dam collapse. The social cost is reduced significantly.

Advantages of LZ-3 over the existing fan-type wind power generation:

For the conventional fan-type wind power generator, it is to receive wind from the normal direction. In fact, each blade of the fan has to be built with a slanted surface. It is only a division of force of the oncoming wind to turn the fan to rotate. That practically reduces the wind impact area. Putting all these into consideration, the conventional fan-type wind power generator is only able to convert a very small faction of the oncoming wind power into electricity. When occupying the same physical dimensions, the wind impact area of LZ-3 is 6 times more than the conventional fan-type wind power generator. In the meantime, the flaps of LZ-3 are facing the oncoming wind directly. The effective output power conversion is estimated 10 times more than the conventional fan-type.

Meanwhile, in order to reduce friction, the alignment of the rotor of the conventional fan-type has to be of high precision. The design of the rotor has to be very sophisticated. It is also demanding to fabricate the fan blades with a proper kind of material. Everything will add up to cost. LZ-3 will be less demanding and that will reduce the cost significantly.

Moreover, the conventional fan-type has to be built on a high supporter. When the wind is high, there will be great risk for the supporter to break up and collapse due to the principle of the lever. Therefore, a high wind limit is set to avoid it. When the wind speed exceeds the limit, it will stop. Generally, the limit is set at 20m/sec. This problem does not exist when using LZ-3. Therefore, LZ-3 can be working in a higher wind speed and consequently will produce more electricity.